Description

Powerful Alkaline Compound for Cleaning & Industrial Use

Trisodium Phosphate (Na₃PO₄), chemically known as sodium phosphate tribasic, is a white, odorless crystalline solid renowned for its exceptional alkaline properties and cleaning capabilities. This versatile inorganic compound serves as one of the most effective degreasing and cleaning agents in industrial applications, offering superior pH buffering capacity and excellent water solubility. With its high alkalinity (pH 11.5-12.5 in 1% solution) and rapid dissolution characteristics, TSP provides unmatched performance in heavy-duty cleaning, water treatment, food processing, and detergent formulation. The compound’s unique phosphate chemistry enables it to bind with metal ions, preventing corrosion while simultaneously breaking down grease, oils, and organic soils through saponification and emulsification processes.

For comprehensive information about phosphate chemicals and their industrial applications, explore the Industrial Phosphate Chemistry Resource to understand the latest developments in phosphate production and processing technologies.

Product Specifications

| Property | Specification |

|---|---|

| Chemical Formula | Na₃PO₄ |

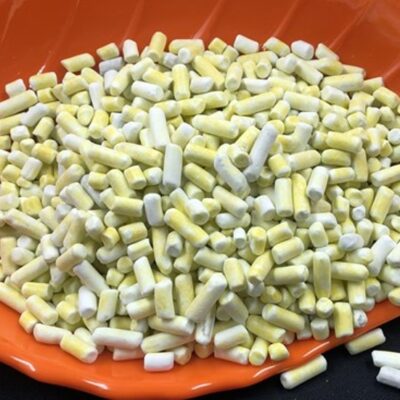

| Appearance | White crystalline powder/granules |

| Purity | ≥ 98.0% (Technical Grade), ≥ 99.5% (Food Grade) |

| Total P₂O₅ Content | ≥ 18.8% minimum |

| Sodium Content | ≥ 31.2% (as Na) |

| Water Insoluble Matter | ≤ 0.10% maximum |

| Heavy Metals (as Pb) | ≤ 10 ppm maximum |

| Arsenic (As) | ≤ 3 ppm maximum |

| pH (1% Solution) | 11.5 – 12.5 |

| Solubility | 100 g/100 mL water at 20°C |

| Moisture Content | ≤ 0.5% maximum |

| Bulk Density | 0.7-1.0 g/cm³ |

| Particle Size | 20-80 mesh (0.2-0.8 mm) |

| Packaging | 25 kg bags, 50 kg bags, steel drums, bulk containers |

Applications of Trisodium Phosphate

Industrial & Heavy-Duty Cleaning (Primary Application)

- Metal degreasing and surface preparation for coating applications

- Industrial equipment cleaning and maintenance operations

- Paint stripping and surface preparation for automotive industry

- Machinery cleaning in manufacturing and processing facilities

Water Treatment & Conditioning

- Municipal water pH adjustment and alkalinity control

- Industrial boiler water treatment for scale prevention

- Cooling tower water conditioning and corrosion inhibition

- Wastewater treatment for heavy metal precipitation

Food Processing & Safety

- Food contact surface cleaning and sanitization

- Food additive (E339) for emulsification and acidity regulation

- Meat and poultry processing facility sanitation

- Beverage production equipment cleaning

Detergent & Cleaning Product Formulation

- Heavy-duty powdered detergent manufacturing

- Industrial cleaning compound production

- Specialty degreasing formulations

- Professional cleaning product development

Ceramic & Glass Manufacturing

- Ceramic glaze preparation and surface treatment

- Glass etching and surface modification processes

- Refractories manufacturing and processing

- Technical ceramics production

Textile & Dyeing Industries

- Fabric treatment and preparation processes

- Dye fixation and color fastness improvement

- Textile cleaning and finishing operations

- Fiber processing and modification

Benefits of Trisodium Phosphate

Exceptional Cleaning Power

Superior degreasing capability removes heavy oils, grease, and stubborn organic soils through alkaline hydrolysis.

Strong Alkaline Properties

High pH (11.5-12.5) provides excellent neutralization of acids and organic contaminants.

Rapid Water Solubility

Complete dissolution in water (100g/100mL at 20°C) ensures uniform distribution and immediate action.

Metal Ion Sequestration

Phosphate groups bind with calcium, magnesium, and heavy metal ions, preventing interference and precipitation.

pH Buffering Capacity

Maintains stable pH levels across wide concentration ranges for consistent performance.

Cost-Effective Performance

Low dosage requirements (1-5%) deliver high-impact cleaning with economic efficiency.

Food Grade Safety

Available in food-grade quality meeting strict regulatory standards for food contact applications.

Corrosion Prevention

Forms protective phosphate films on metal surfaces, preventing oxidation and deterioration.

Industrial & Heavy-Duty Cleaning Applications

Metal Surface Preparation

- Degreasing steel, aluminum, and other metals before coating

- Removal of machining oils and cutting fluids

- Paint stripping and surface etching for improved adhesion

- Rust and scale removal from metal components

Equipment & Machinery Cleaning

- Industrial machinery degreasing and maintenance

- Food processing equipment sanitization

- Automotive parts cleaning and restoration

- Manufacturing equipment cleaning and preparation

Surface Preparation for Coatings

- Phosphate conversion coating preparation

- Surface profiling for paint and powder coating

- Cleaning before galvanizing and plating operations

- Preparation for welding and fabrication processes

Professional Cleaning Services

- Commercial kitchen deep cleaning operations

- Industrial facility maintenance and cleaning

- Restoration and remediation cleaning projects

- Specialized decontamination procedures

Water Treatment Applications

Municipal Water Systems

- pH adjustment for corrosion control in distribution systems

- Alkalinity enhancement for water stability

- Scale prevention in water mains and service lines

- Sequestration of metal ions causing discoloration

Industrial Water Treatment

- Boiler water treatment for scale and corrosion prevention

- Cooling tower water conditioning and biofouling control

- Process water preparation for manufacturing operations

- Reverse osmosis pretreatment for membrane protection

Wastewater Treatment

- Heavy metal precipitation and removal processes

- pH neutralization of acidic industrial effluents

- Phosphorus removal enhancement in biological treatment

- Sludge conditioning for improved dewatering

Specialized Water Applications

- Swimming pool pH control and alkalinity adjustment

- Aquaculture water quality management

- Hydroponics nutrient solution preparation

- Laboratory water preparation and treatment

Food Processing Applications

Food Contact Surface Cleaning

- Stainless steel equipment cleaning in dairy processing

- Meat and poultry processing facility sanitation

- Bakery equipment cleaning and maintenance

- Beverage production line cleaning and sanitization

Food Additive Applications (E339)

- Emulsification in processed cheese production

- Acidity regulation in canned and preserved foods

- Texture modification in meat and seafood products

- pH control in beverage manufacturing

Cleaning & Sanitization

- HACCP-compliant cleaning procedures

- CIP (Clean-in-Place) system formulations

- Manual cleaning solutions for food equipment

- Sanitization of food contact surfaces

Quality Control Applications

- pH adjustment in food processing operations

- Metal ion control in food preservation

- Texture enhancement in processed foods

- Shelf-life extension through pH management

Detergent & Cleaning Product Manufacturing

Heavy-Duty Detergent Production

- Builder function in powdered laundry detergents

- Soil suspension and redeposition prevention

- Water softening through metal ion sequestration

- pH enhancement for optimal cleaning performance

Industrial Cleaning Formulations

- Degreasing compound manufacturing

- Metal cleaning solution production

- Concrete and masonry cleaner formulation

- Automotive cleaning product development

Specialty Cleaning Products

- Paint stripping formulations

- Rust removal and conversion products

- Professional kitchen cleaning compounds

- Marine and industrial maintenance cleaners

Commercial Cleaning Solutions

- Floor cleaning and maintenance products

- Wall and surface cleaning formulations

- Graffiti removal and surface restoration

- Equipment cleaning and sanitization products

Ceramic & Glass Manufacturing Applications

Ceramic Production

- Glaze preparation and surface treatment processes

- Clay processing and purification operations

- Ceramic firing and sintering processes

- Technical ceramics manufacturing

Glass Processing

- Glass etching and surface modification

- Container glass manufacturing processes

- Optical glass preparation and treatment

- Specialty glass production applications

Refractories Manufacturing

- Refractory brick and shape production

- High-temperature material processing

- Furnace lining and insulation manufacturing

- Crucible and vessel production

Textile & Dyeing Applications

Fabric Treatment

- Cotton and synthetic fiber preparation

- Mercerization and finishing processes

- Fabric softening and conditioning

- Textile printing preparation

Dye Processing

- Dye bath preparation and pH control

- Color fastness improvement

- Mordant preparation and application

- Fabric dyeing process optimization

Finishing Operations

- Fabric washing and cleaning processes

- Stain removal and restoration

- Textile coating and treatment

- Quality control and testing procedures

Quality Control & Testing

Chemical Analysis

- Phosphate content determination by gravimetric analysis

- Sodium content by flame photometry or ICP

- pH measurement and buffering capacity testing

- Heavy metals analysis by atomic absorption spectroscopy

Physical Properties Testing

- Particle size distribution by sieve analysis

- Bulk density measurement for packaging optimization

- Moisture content determination by loss on drying

- Dissolution rate testing for application suitability

Food Grade Testing

- Microbiological testing for food applications

- Heavy metals screening for safety compliance

- Arsenic and lead content verification

- Fluoride content analysis for regulatory compliance

Performance Testing

- Cleaning efficiency evaluation under standard conditions

- pH stability testing across temperature ranges

- Solubility verification at various temperatures

- Compatibility testing with other chemicals

Storage & Handling

Storage Requirements

- Store in cool, dry, well-ventilated warehouses

- Maintain temperature below 30°C to prevent caking

- Protect from moisture and humidity exposure

- Use moisture-resistant packaging and storage containers

- Separate from acids and acidic materials

Handling Precautions

- Wear appropriate personal protective equipment (PPE)

- Use dust masks and eye protection during handling

- Ensure adequate ventilation in processing areas

- Avoid generating dust clouds during transfer operations

- Use proper lifting techniques for heavy bags and containers

Safety Measures

- Install emergency eyewash stations and safety showers

- Provide first aid equipment for alkali exposure

- Implement spill containment and cleanup procedures

- Train personnel in safe handling practices

- Maintain Safety Data Sheets (SDS) in accessible locations

Environmental Considerations

Sustainability Features

- Phosphate recycling and recovery from waste streams

- Biodegradable properties in aquatic environments

- Renewable feedstock utilization in production

- Energy-efficient manufacturing processes

Environmental Impact

- Controlled phosphate discharge to prevent eutrophication

- Waste minimization in production and packaging

- Recyclable packaging materials for sustainability

- Environmental monitoring and compliance programs

Waste Management

- Proper disposal procedures for contaminated materials

- Spill cleanup and neutralization protocols

- Packaging waste reduction and recycling programs

- Environmental impact assessment and mitigation

Packaging & Delivery Options

Standard Packaging

- 25 kg PP Bags – Ideal for small to medium-scale operations

- 50 kg PP Bags – Standard for industrial applications

- Steel Drums (200 kg) – Moisture protection for long-term storage

- Bulk Containers (1000 kg) – Cost-effective for large-scale use

Specialized Packaging

- Moisture-proof laminated bags for humid climates

- Food-grade packaging for food processing applications

- Anti-static bags for electronic and sensitive applications

- Custom packaging solutions for specific requirements

Global Distribution Network

- Climate-controlled warehouses for product integrity

- Specialized transportation for hazardous materials

- Fast delivery across South Africa, SADC, and international markets

- Technical support and application assistance

Technical Support Services

Application Support

- Cleaning formulation development assistance

- Process optimization for specific applications

- Dosage recommendations for various soil types

- Troubleshooting and performance improvement

Training Programs

- Safe handling and storage procedures

- Application techniques for optimal performance

- Quality control and testing procedures

- Environmental compliance and safety protocols

Consultation Services

- Custom formulation development

- Process audits and improvement recommendations

- Cost optimization analysis

- Regulatory compliance assistance

Regulatory Compliance

Food Industry Standards

- FDA approval for food contact surface cleaning

- USDA compliance for meat and poultry processing

- HACCP compatibility for food safety systems

- Kosher certification for religious requirements

Industrial Standards

- ISO quality management system compliance

- ASTM material specifications conformance

- European chemical safety regulations (REACH)

- Occupational health and safety standards

Environmental Regulations

- Water discharge permit compliance

- Air quality emission standards

- Waste disposal and treatment regulations

- Environmental monitoring and reporting requirements

For detailed chemical safety data sheets and regulatory compliance information for all our industrial chemicals, visit our Chemical Safety & Compliance Hub.

Why Choose Our Trisodium Phosphate?

Superior Purity & Quality

Advanced manufacturing processes and rigorous quality control ensure consistent product quality and performance reliability.

Technical Expertise

Experienced technical team provides comprehensive support for application optimization, formulation development, and process improvement.

Reliable Supply Chain

Strategic inventory management and established supplier relationships ensure consistent product availability throughout the year.

Competitive Pricing

Cost-effective solutions through efficient operations, bulk purchasing, and optimized logistics for maximum customer value.

Global Reach

Extensive distribution network enables fast, reliable delivery to customers across South Africa, SADC, and international markets.

Comprehensive Support

Complete technical support services including application guidance, training programs, and ongoing customer assistance.